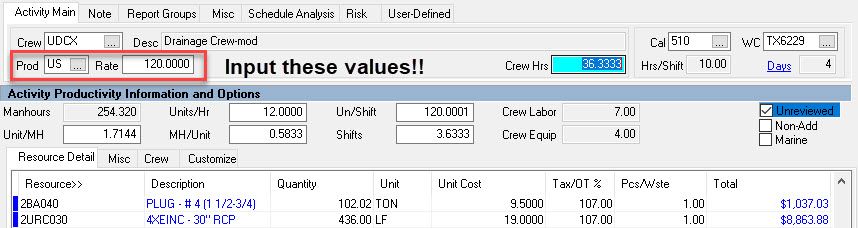

Best Practice-Enter Rate of Production

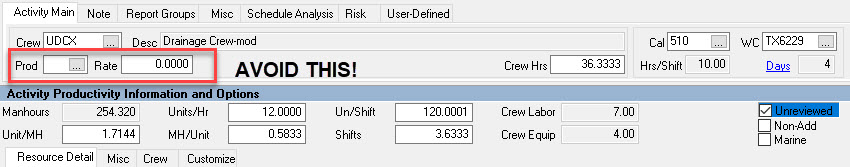

In my HeavyBid training I emphasized with users that just inputting total crew hours instead of a production type and rate should be avoided.

I always have known by intuition that entering production type and production (ie Units per Hour) is superior to just entering crew hours. But why? I just finished a book on the perception of time and in a section titled “The Planning Fallacy” the author references two well-known construction projects where the completion date was delayed by years. No surprise to anybody reading this blog. What I found fascinating is that a book has nothing to do with construction but when this subject of false expectations was discussed the author referred to errors in construction estimating as an example. Shocker. Here is a section of the chapter:

The planning fallacy was first proposed by Daniel Kahneman and Amos Tversky in 1979. It is essentially a biased internal conviction that a current project will go as well as planned, even though similar projects from the past have failed to fulfill their planned outcomes. The future is perceived to be rosier than the past. Lessons from the past fade from our attention in light of optimistic plans about the future. Research has shown that people, on average, underestimate how long it takes to do things by a significant 40 percent! From “The Power of Time Perception” by Jean Paul Zogby

So the scientific reason that durations are underestimated in determining the total estimate of time (crew hours) is that estimators are over-optimistic even with past history that would contradict the crew hours duration. Sure an estimator can overestimate the production rate but from my observations a lot less thought is put into entering a value in Crew Hours. When an estimator just “guesstimates” the crew hours he or she is more than likely it is on the optimistic side. Let’s do an example:

Task: Drive 16 piles at a bridge pier

Method 1: Estimator enters 50 crew hours. No production is considered. This is a gut feel number. Duration: 50 hours

Method 2: Productivity Method: Estimator knows that based on historical productions they can drive 2.5 piles per day which includes pre-drill and template erection (which could be separate activities).

Duration: 16 pile / 2.5 piles per shift = 6.4 shifts x 10 hours/shift = 64 hours

There is a big difference in cost between the two. Now true if the estimator is using HeavyBid they will see units/shift and units/hour but again my observation is that if an estimator that is just “guesstimating” total duration the two values are not considered or even noticed by the estimator. And why should it be? They are guessing using the “gut feeling” method.

Using best practice of entering a production type and production rate you can still overestimate a true value but you are much more likely to err towards the conservative more historical value than total crew hours that we as optimistic estimators would enter.

Two reasons I see estimators not using the production type. First is they were not taught proper estimating best practices. I see this a lot in self-taught estimators. The second is they are just lazy and don’t want to think about a production value. Estimating is not a place for guessing and for larger projects it can be disastrous.

Conclusion: Look at your team’s estimates and challenge those leaving the production type and rate blank and just entering total crew hours. Start using best practices of setting production rates to let crew hours be calculated. Not only is this an important best practice of estimating but it is how HeavyBid was designed to work.

More thoughts on this in another blog on the above.